Different types of industries and applications require a range of different types of aluminum extrusion shapes. Of course, some shapes are used throughout different industries and applications, with these often becoming known as stock aluminum extrusions.

There are several important factors that make specific aluminum extrusion shapes more applicable to different industries. In some situations, the shape is designed to provide structural stability, such as a rod or bar.

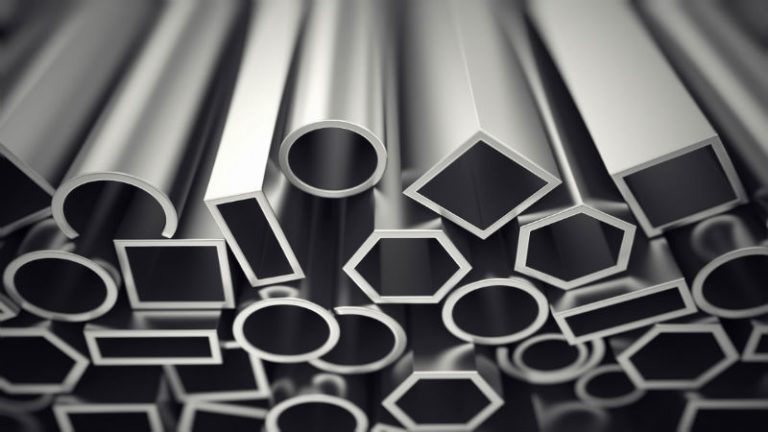

These standard shapes can include a bar that is square, round or flat. There is also an aluminum rectangular bar, which is used throughout many different fabrication and manufacturing processes. These basic shapes can be further machined or worked to create more elaborate shapes.

Hollows

It is possible to create different hollow shapes that are used in a range of different manufacturing in the aerospace, aeronautics and the military and defense industries. These same shapes are also used in construction and manufacturing of everything from trailers and boats to camping gear and sporting goods.

Hollow stock extrusions include tubes, squares and rectangles. There is also the option to have structural pipe, which is different from a tube, as a standard option for many aluminum uses.

Channels

Channel is used in construction, fabrication and design. It is also used in the creation of vehicles, trucks and trailers as well as marine vessels. It is a strong structural component and different alloys will provide high strength to weight ratios as well as different levels of corrosion resistance.

Channel comes with a range of different types of corners and interior channel shapes. The two most common are structural channel, which has a more sloped interior shape and the square corner channel. These are considered stock or standard aluminum extrusion shapes and are readily available through most metal and aluminum suppliers.

Beams

Aluminum beams are used in construction as they are strong, durable and non-flammable. The two most common shapes of beams are the I-beam and the H-beam. These are named due to the shape they create when viewed in profile.

The I-beam has 90-degree internal angles and looks like a capital “I” when turned on one end. The H-beam has a more tapered or graduated angle at the four internal corners, creating the look of a capital H when viewed on its side.

There are also angles that are made from aluminum that are used in construction and fabrication as well as aerospace and automotive design. These are also readily available in a wide range of standard sizes and designs.